Whether it is a manufacturing unit, warehouse, workshop, or fabrication plant, moving heavy materials safely and quickly is a daily requirement. Manual handling is slow, risky, and not practical for growing businesses. This is where lifting cranes play a very important role. Among different lifting solutions, a Single Girder EOT Crane has become a popular choice for many industries. Businesses are now looking for equipment that is reliable, cost-effective, and easy to operate. A single girder crane fits these needs perfectly, which is why its demand is growing steadily.

What Exactly Is a Single Girder EOT Crane?

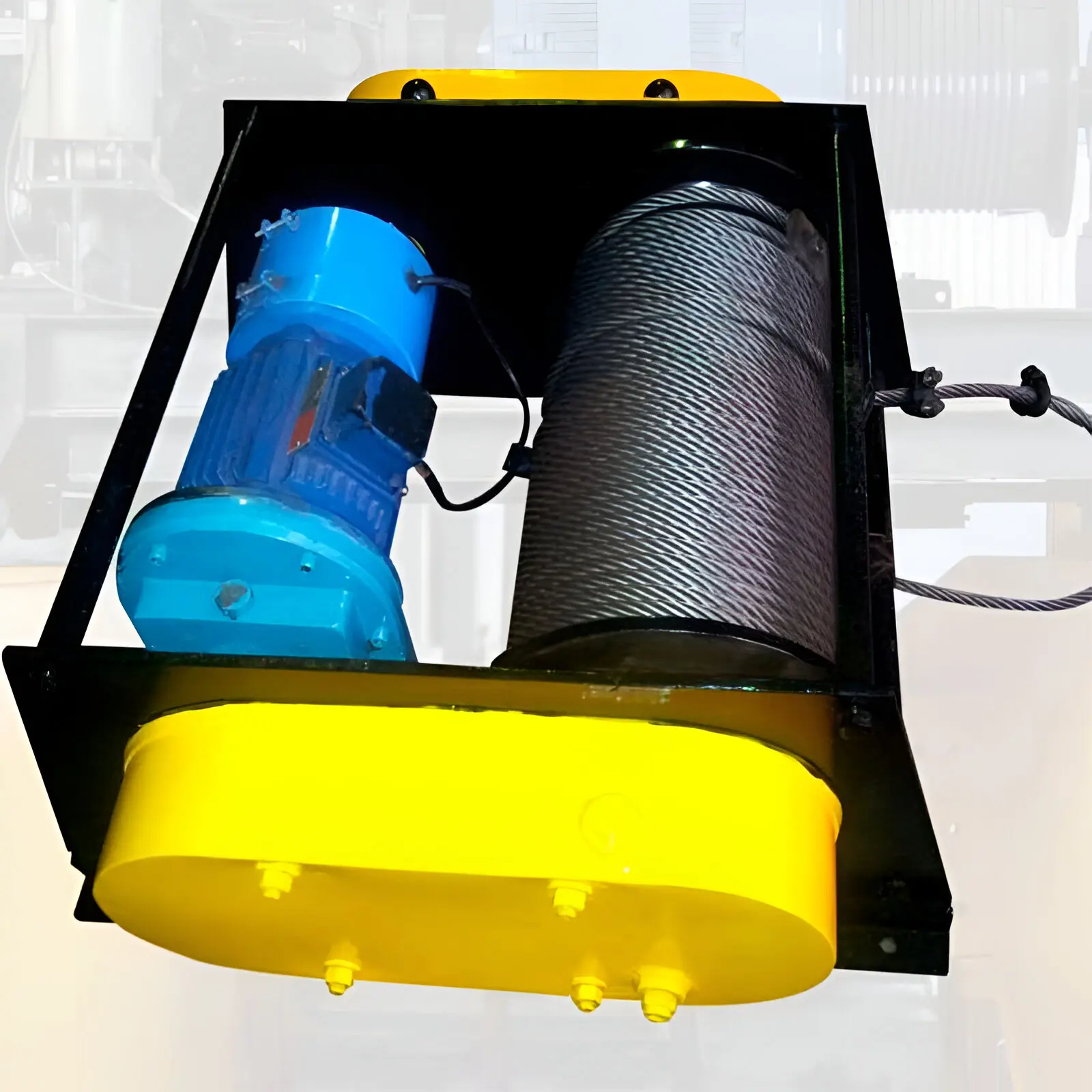

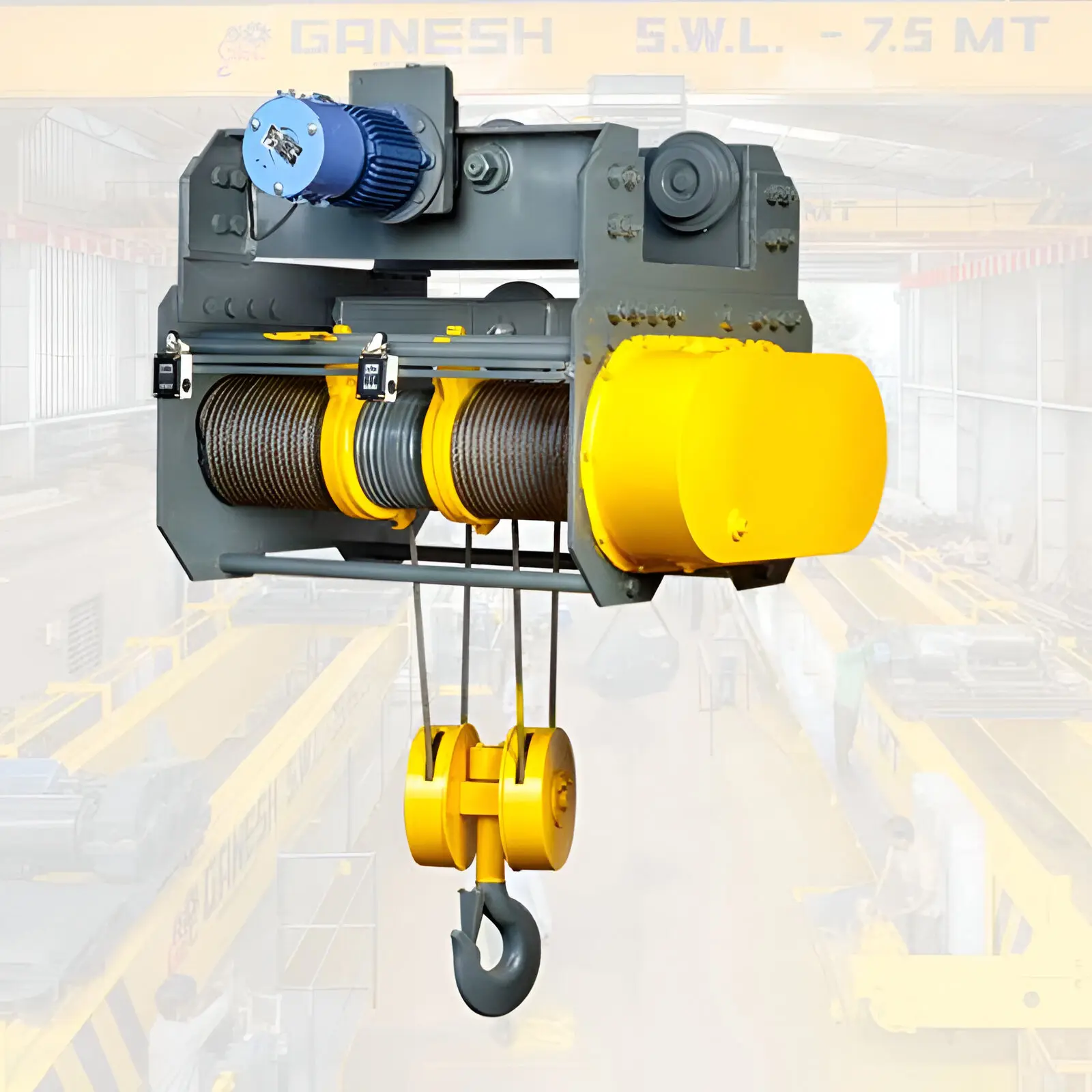

For those new to the industry, an EOT Crane is an overhead crane that operates on parallel runways. An electric overhead travelling crane moves on rails fixed on your building structure. A Single Girder version means it has one main cross-beam that supports the trolley and hoist.

Because it’s built with one beam instead of two, it puts less stress on your building’s structure. Many small and mid-size factories prefer this crane because it does the job without unnecessary complexity.

Where Are Single Girder EOT Cranes Commonly Used?

You’ll find these cranes in almost every industry where efficiency is the top priority. Because they are so versatile, they fit into spaces where bigger cranes just can’t go. Here are some of the most common spots:

- Manufacturing plants

- Warehouses

- Workshops

- Assembly lines

- Textile & paper mills

- Engineering workshops

- Small to medium fabrication units

Why Industries Choose Single Girder EOT Cranes

One main reason is practicality. This crane is easier to install and maintain. It also puts less load on the building structure. Some simple advantages are:

Better Use of Space: Because these cranes are compact, the hook can actually get closer to the walls. In a tight workshop, every inch of floor space is money.

Lower Maintenance Costs: There are fewer parts to break. It’s that simple. In a busy 24/7 environment, you want a machine that stays on the job, not one that’s constantly waiting for a mechanic.

Quick Installation: Time is money. You can get a Single Girder EOT Crane up and running much faster than more complex systems, meaning your production starts sooner.

Safety First: Modern controls mean these cranes are incredibly smooth. No jerking, no swinging, just accurate movement that keeps your workers safe and your inventory intact.

How an EOT Crane Makes Daily Work Easier

Using an EOT Crane reduces physical effort. Workers do not need to lift or drag heavy items. The crane handles the load and places it accurately. This helps reduce injuries and fatigue. Work moves faster, and production stays on schedule. Over time, this improves overall efficiency inside the factory.

Things to Think About Before Buying One

Before purchasing a Single Girder EOT Crane, it is important to understand actual requirements. Some basic points to check:

- How much weight needs to be lifted

- Required lifting height

- Lifespan of the crane

- How often it will be used

- Safety features and controls

Conclusion

An EOT crane is used every day and handles heavy loads. Choosing a crane isn’t just about the price; it’s about the support you get after the machine is installed. This is where Ganesh Engineering Co. truly stands out. As a premier manufacturer and supplier, we’ve spent years perfecting their designs to handle the tough conditions of Indian factories.

We provide a lifting solution that’s built for the long haul. Our Single Girder EOT Crane units are famous for being rugged, safe, and whisper-quiet. Whether you’re a client looking for a bulk order or a small business owner needing a custom setup, we have the technical expertise to make it happen.

Ganesh Engineering

Ganesh Engineering Co. has been a leading manufacturer of Materials Handling Equipment in India since 2004. In order to provide top-notch products and services, our experienced and dedicated team utilizes the latest technology to achieve perfection.