Single Beam Crane

5mtrs. to 50mtrs.

1ton to 10ton

Class-I to Class-IV (M1-M8)

Floor operated through pendent pushbutton station (Optional remote or cabin Operated)

Short details of Single beam crane

We have been working in this field for a long now, and now we will not mind calling ourselves one of the finest in the field of cranes. We manufacture, trade, and also supply single beam cranes. We will be proud of calling us as the specialist of single beam cranes suppliers in India. Cranes are manufactured with the finest of raw materials and very advanced technology at a very reasonable price. It also depicts international standards. It is specified according to the specifications that are laid up by the clients. Clients can avail of the cranes at the best price. We are the best single beam cranes in the manufacturer in India

- Dimensional accuracy: dimensions play an important role in the lifting up of the loads. We are very accurate at these, we provide accurate dimensions for the cranes.

- Easy to install: cranes are very easy to install. These can be moved from one place to another easily and fewer efforts are needed.

- Unmatched quality: the quality that is provided by us is very high and cannot be matched with any other. High-quality raw materials are used for the manufacturing of the canes.

You can get the best of the cranes with us in the market. We are well known for the quality of we provide to our clients at very reasonable prices. We are best suited and well established in the markets and work according to the requirements of the clients. We are very professional with our work and teams are well maintained and have a great knowledge of the work.

Other Details Of The Single Beam Crane

- Manufacturing Range

- Specifications

- Standard Features

- Optional Features

- Safety

- Packing & Forwarding

- Pre-Sales Service

- After-Sales Service

- Manufacturing Range

- 1t. to 10t. Cap., up to 50-meter span and required Height of lift (for Higher Capacity and span please consult us)

- 1t. Cap. Single Beam EOT Crane

- 2t. Cap. Single Beam EOT Crane

- 3t. Cap. Single Beam EOT Crane

- 5t. Cap. Single Beam EOT Crane

- 7.5t. Cap. Single Beam EOT Crane

- 10t. Cap. Single Beam EOT Crane

- Specifications

- Standard Features

- Simple and optimum Design ensuring minimum dead weight, Wheel Load Headroom and easy to maintenance

- Easy to installation

- Reliable structure

- Higher efficiency to save power

- All motions are protected with Fail safe type brakes (which are applied when power supply is off and release when power supply is on.)

- All motions are protected with limit switches

- Rubber buffers are provided to extra protection against collision in case of limit switch failure

- Dustproof panel box with reputed make switch gear or as per customer’s approval

- 110 V Control voltage selected for protection of Crane operator against any electrical shock

- With electrical Interlocking to prevent simultaneous operation of opposite motion

- Using "C' Rail / I Section type C.T. & Push button Festoon system it’s give long life and trouble free operation

- Unbreakable, Handy, light weight PVC Pushbutton

- Coupling less L.T. & C.T. Motion up to 7.5 Hp, (Less mechanism less maintenance)

- VFD in Long Travel Motion, Smooth Start & Stop (Maximize the life of Mechanism)

- Own Make Gearbox so which are easy to maintenance and we can provide any parts at any time from our stock

- Platform with hand railing for easy, simple & safe maintenance of the crane extended partially or totally along the girder width

- Optional Features

- Radio Remote Control / Cabin Control

- Dual speed for all motion

- VFD in all motion

- Siren While Traveling a crane

- Load Cell with Display to weigh a Load or protection against overload

- Special Dimension Hook

- Other Reputed Brand Gearbox

- Drag Chain in Festoon system

- Protective Paints / Coating

- Safety

- Over Lowering or over hoisting prevention limit switch

- Hook Safety Latch

- Overload Relays

- Travelling limit switch

- Rubber buffer

- Brakes in Hoisting as well as c.t & L.T.

- Main Switch

- On/ off switch in push button /Emergency stop

- MCB /fuse

- All 4 core cables with Earth cable

- Maintenance platform

- Siren in goliath crane

- Anti-collision device when more than one crane on same bay

- Packing & Forwarding

- Pre-Sales Service

- One to one service guarantees you the best purchasing experience.

- Strong production capacity and professional workmen guarantee you the short delivery.

- Strict delivery inspection guarantees you the high quality products.

- The short delivery time.

- After-Sales Service

- One year warranty for Cranes

- Providing free quick-wear part

- Low charge for continue maintenance when warranty is expired

- Exclusive engineer support at any time.

- Highly professional training to end-users

| Descriptions | Specifications |

| Area | Non Hazardous/Hazardous as per customer requirement |

| Test Load | 125% of SWL |

| IS Code | IS807, IS3177 |

| Type | Single Girder |

| Locations | Indoor/Out door |

| End Carriages | The End Carriages are welded construction type and fabricated from plates or Std. section type constructions. |

| Bridge Girders | The girder is of plate fabricated box type construction design to sustain all stresses arising due to vertical & lateral forces with impact to which they are subjected. The maximum deflection of the main girder is limited to 1/750 the span of live loads including the weight of the trolley or hoist. |

| Platform | Two small length platform shall be provided |

| End Stopper | Steel end stoppers are provided on either side of the bring to limit the motion of the trolley. All the buffers will employ springs for shack absorption. |

| Steel | Steel confirming to IS-2062 or equivalent is used in the manufacturing of the main load bearing. (Mainly Essar or Sail make) |

| Wheel Base | As per span and IS code |

| L.T. Drive System | Twin drive type. |

| Main-Hoisting | 3.5 meter per minute (micro speed will be provided on demand) |

| L.T. | 20 meters per minute (micro speed will be provided on demand) |

| C.T. | 15 meters per minute (micro speed will be provided on demand) |

| Ele. Motors | All motors are off S-4 duty, Squirrel cage ,40% CDF,150 S/hr., IP -55 with Class F insulation or as per required class and duty |

| Brakes | Electro Hydraulic shoe type/ Electromagnetic Disc / Electromagnetic Shoe type brake shall be provided in Hoisting L.T. & C.T. These brakes are automatically released when the motor circuit is on and is applied the motor circuit is off |

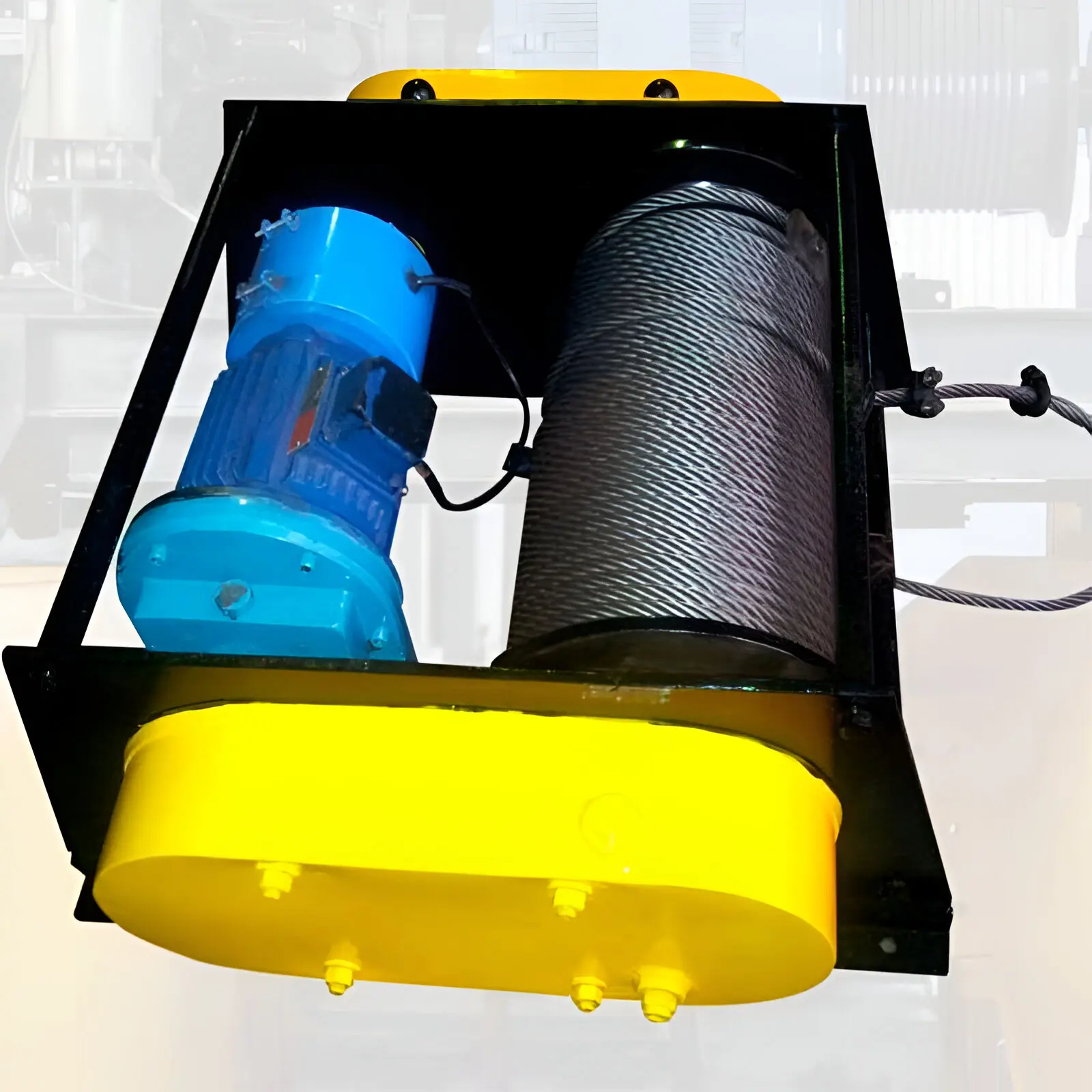

| Wire Rope & No. ofaal | Selected as per crane capacity and IS Code he make of wire rope will be used Usha-martin |

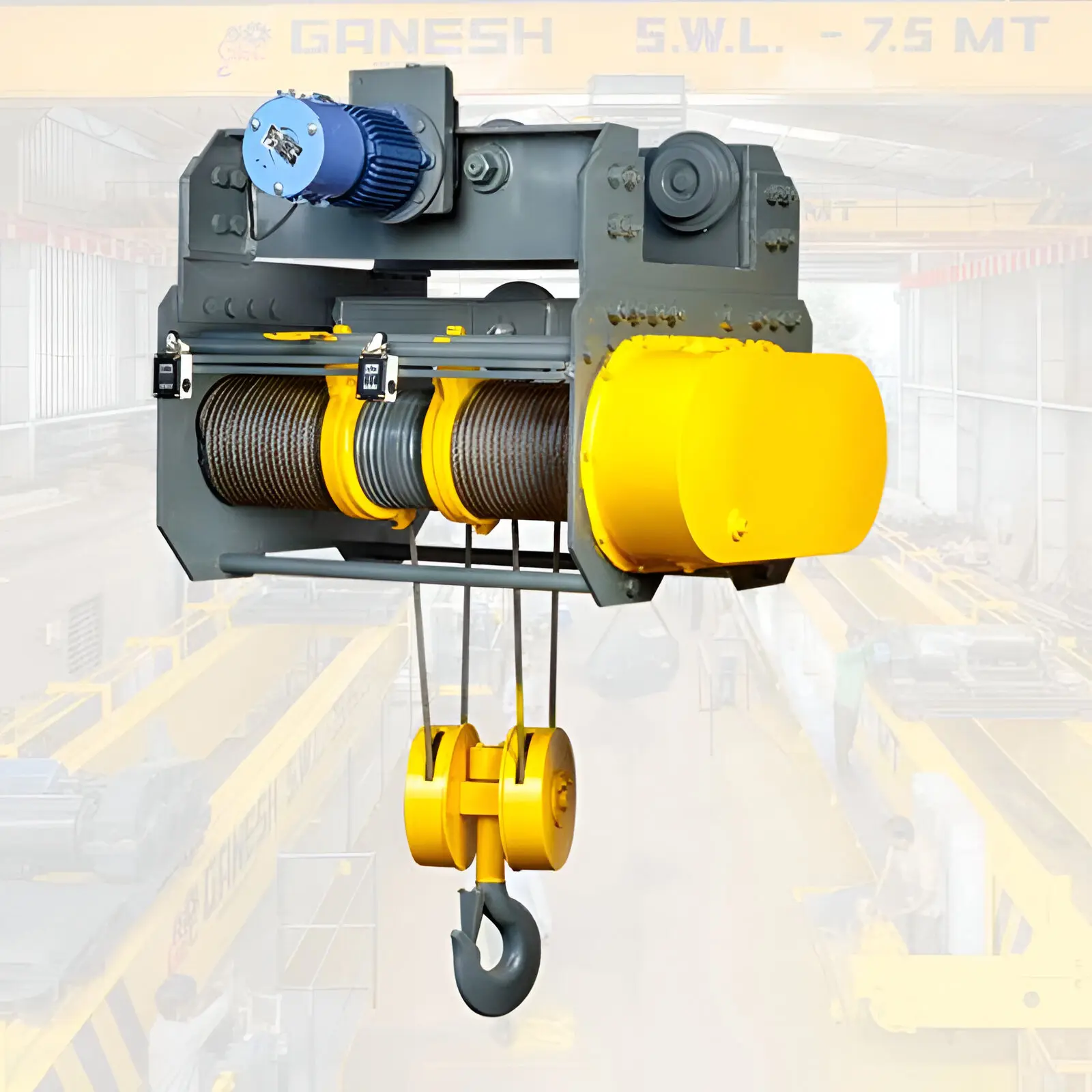

Various Components Single Beam Crane