As one of the material handling systems, the EOT crane is a dependable and secure alternative for a wide range of industrial applications. The EOT crane is available with both single and double girders. Single Girder EOT Cranes are a practical option for warehouses and small industrial facilities. It can also be used to treat a hot metal ladle in some instances. A single girder crane has an ideal capacity of roughly 20 MT and can span up to 50 meters.

An Overview of Single Girder EOT Crane

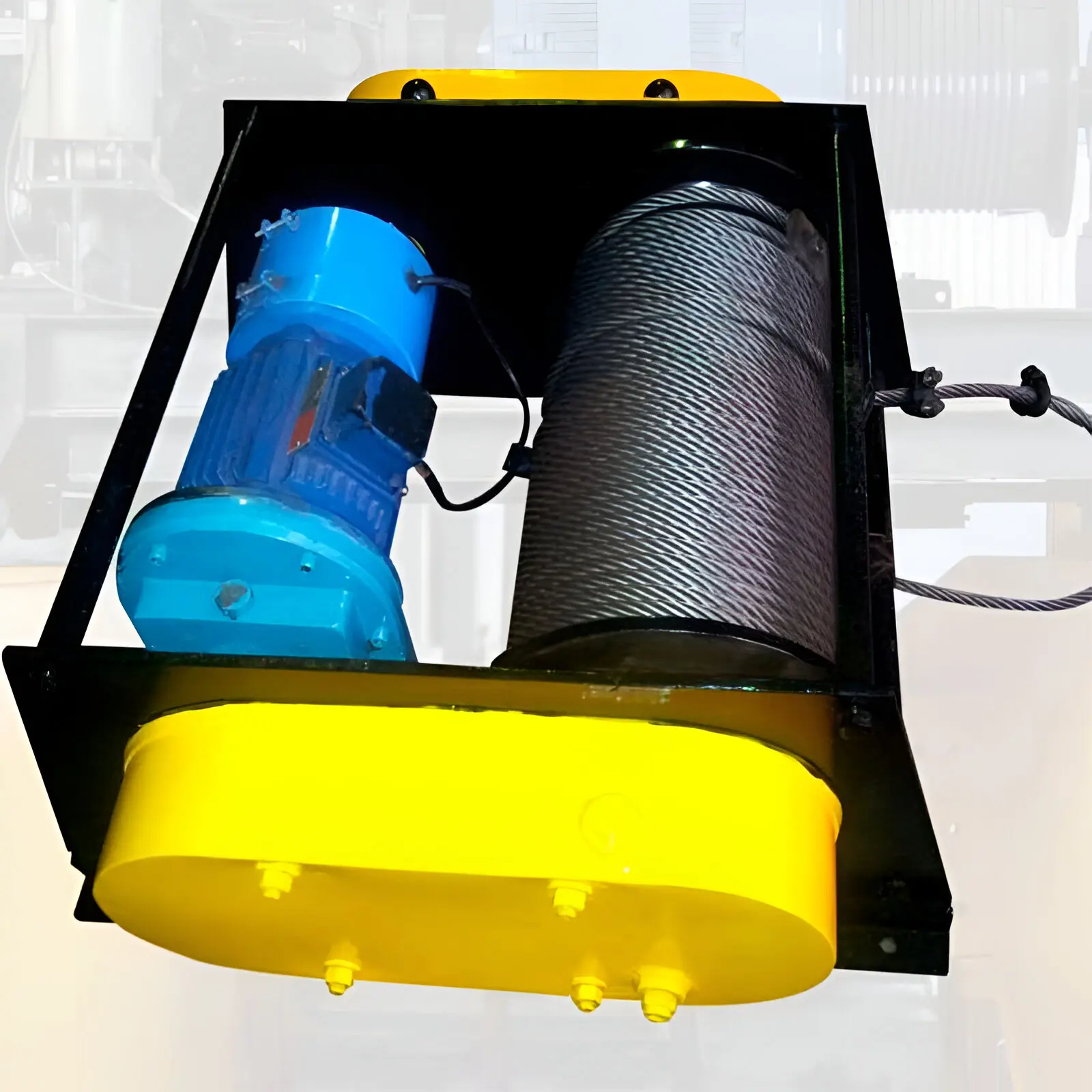

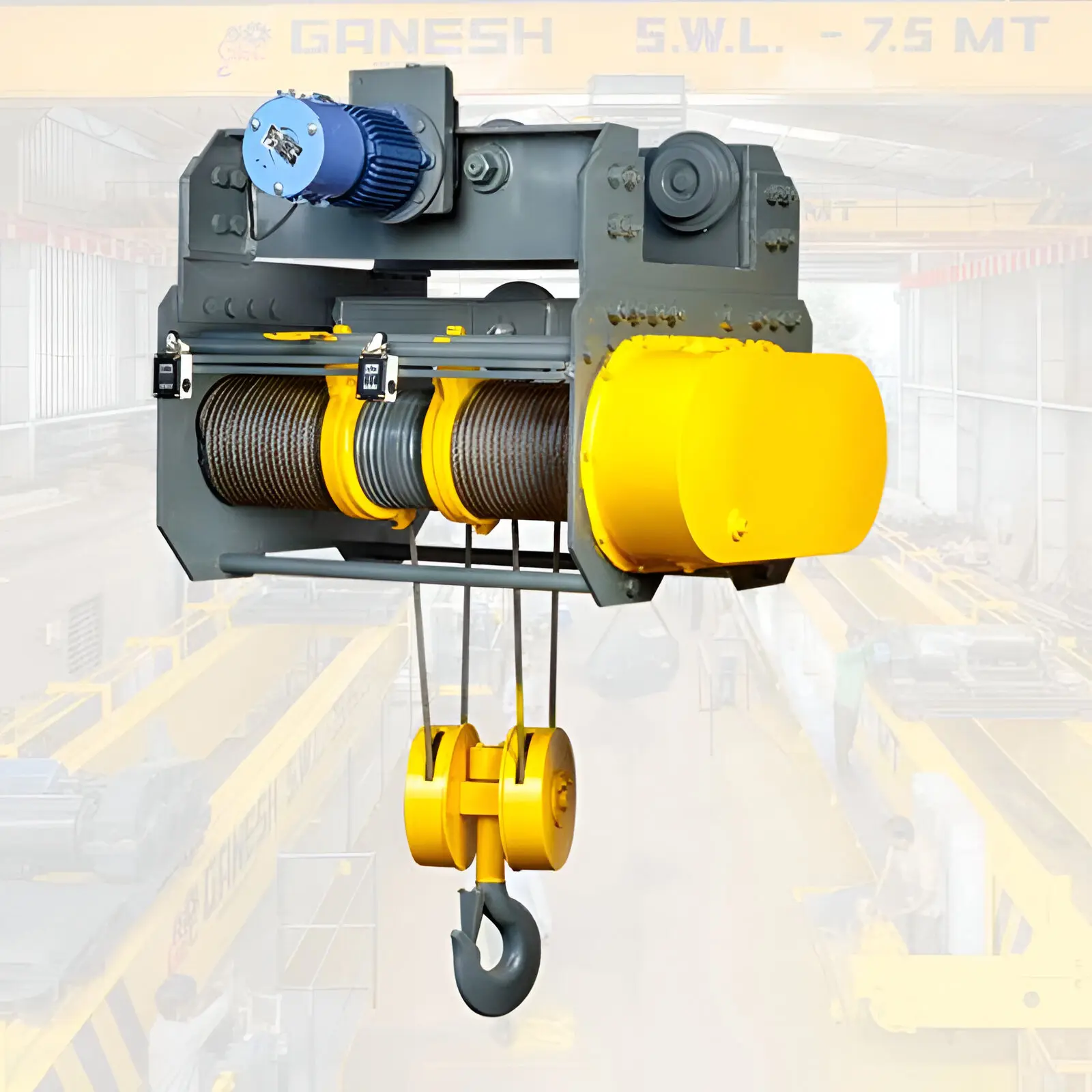

A Single Girder Crane has one main girder between the parallel runways. It comprises an electric hoist that travels along the bottom flange of the main girder. This EOT crane does not require the rail component to move on the parallel runway. Because of its compact size and modular design, this crane can lift heavy loads. This single girder EOT crane has been constructed with high-quality wire rope hoists. In general, a single girder crane does not have platforms. However, in other circumstances, it comprises two tiny platforms for the Long Travel (LT) mechanism.

Features of a Single Girder EOT Crane

This crane is equipped with a wireline, hook, electric motor brake, drum, pulley, and other components. It rides on tracks attached to gantry girders. An EOT crane’s main construction is a bridge girder constructed of U, I, and other rolled pieces. There are two end carriages to support this bridge girder, each with two wheels. A wire rope hoist is hung beneath the bridge girder.

It also includes flanged-mounted motors and vertical gearboxes. It may be controlled with a push-button pendant station dangling from the rope hoist or a radio remote control. However, the crane cannot be operated from the cabin. DC (Direct Current) Disc Brakes are utilized for all crane operations.

The single girder cranes employ a snap action limit switch to control the movement of the hoist upward or downward. This switch is activated by a wire rope guide. The single girder EOT crane has four wheels in an LT (Long Travel) end carriage. As a result, the crane’s wheel load is higher, and a heavier gantry girder is necessary to increase capacity. Single girder cranes are used for light tasks such as handling standard materials.

How It Handles Heavy Loads Efficiently

- Many people assume that a single girder EOT crane is only suitable for light-duty applications, but modern engineering has made them capable of handling surprisingly heavy loads.

- The girder and supporting parts are made from robust steel that can bear heavy loads without bending or vibration.

- Electric wire rope hoists or chain hoists used in these cranes are designed to lift heavy materials easily and with accurate speed control.

- The latest single girder cranes come with advanced control systems that allow smooth lifting and traveling, even with large or delicate loads.

- Overload limiters, emergency stop buttons, and safe start functions prevent accidents and protect both machines and workers.

Conclusion

A single girder EOT crane is a strong material handling equipment. It can handle heavy loads easily and reduces manual effort. If you need durable lifting solutions, Ganesh Engineering is your ideal choice. We are one of the top EOT crane manufacturers that offers high-quality products.

Ganesh Engineering

Ganesh Engineering Co. has been a leading manufacturer of Materials Handling Equipment in India since 2004. In order to provide top-notch products and services, our experienced and dedicated team utilizes the latest technology to achieve perfection.