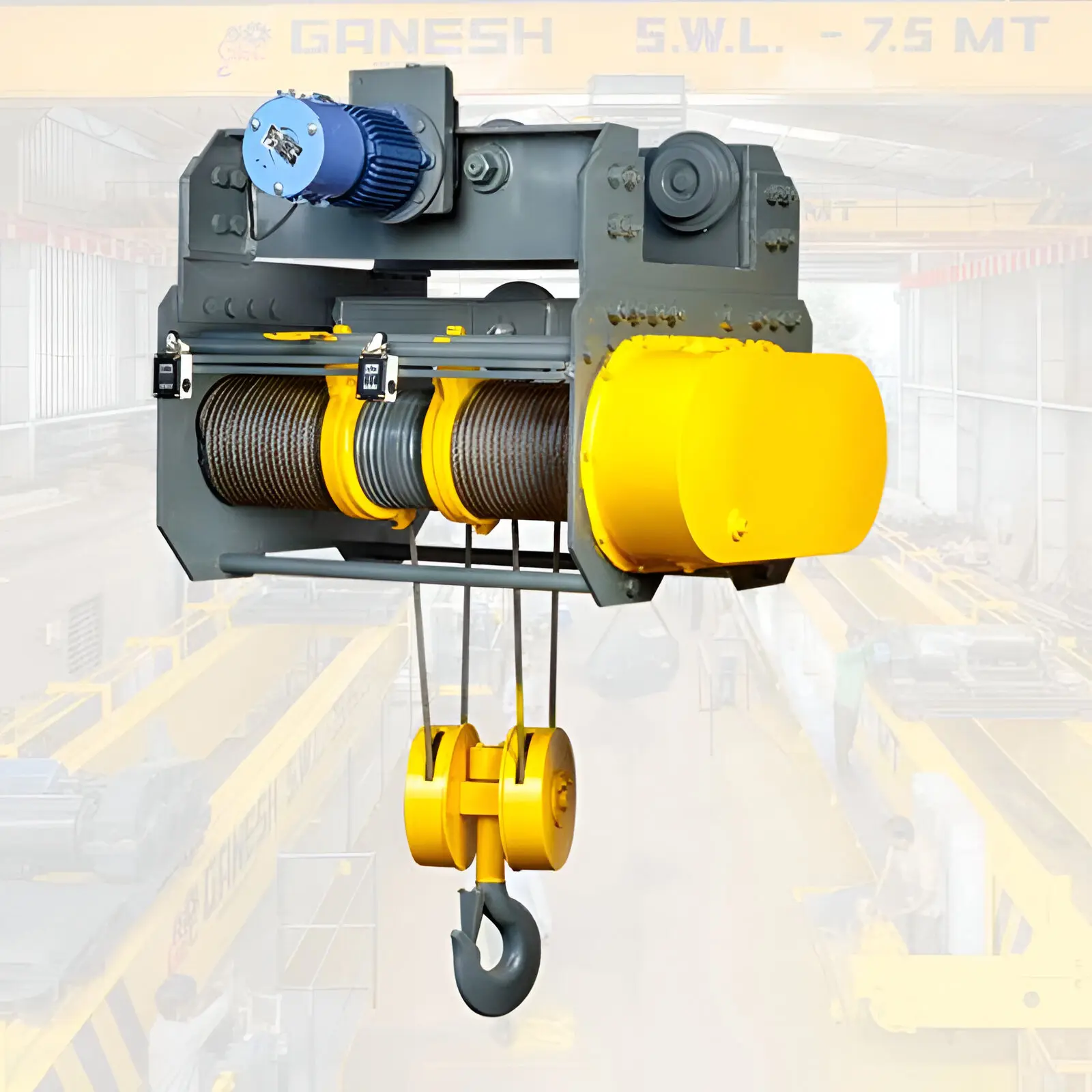

Some of the industries, like warehouses, automobile, railways, and paper mills, always require moving heavy loads. It is not possible to move the load manually. Not only will it increase the cost of labor, but it will also chances of mishaps and accidents as the load is really heavy. The EOT (electric overhead traveling) crane is the best solution for moving heavy loads precisely. It will reduce the operational cost, and the move will be done smoothly.

The EOT crane is an overhead bridge crane that uses electricity to lift and move heavy loads. It reduces downtime, ensures safety, and maintains optimal performance. However, this equipment will function well only when it is in good condition. Here are some of the common problems faced by the EOT crane and tips to fix them.

Crane is not starting

If the crane is not starting, you should take this seriously, as it is not just a power failure. It could be due to various factors, like electrical issues, malfunctioning circuit breakers, or a blown fuse. It could be due to a problem with the crane’s control panel, a faulty transformer, or issues with the crane’s battery. So, check the power supply to ensure that it is properly connected to the electrical system and the main power is ‘on’. Make sure that the power supply cables are not damaged. Apart from that, inspect the control panel to ensure that there are no error codes.

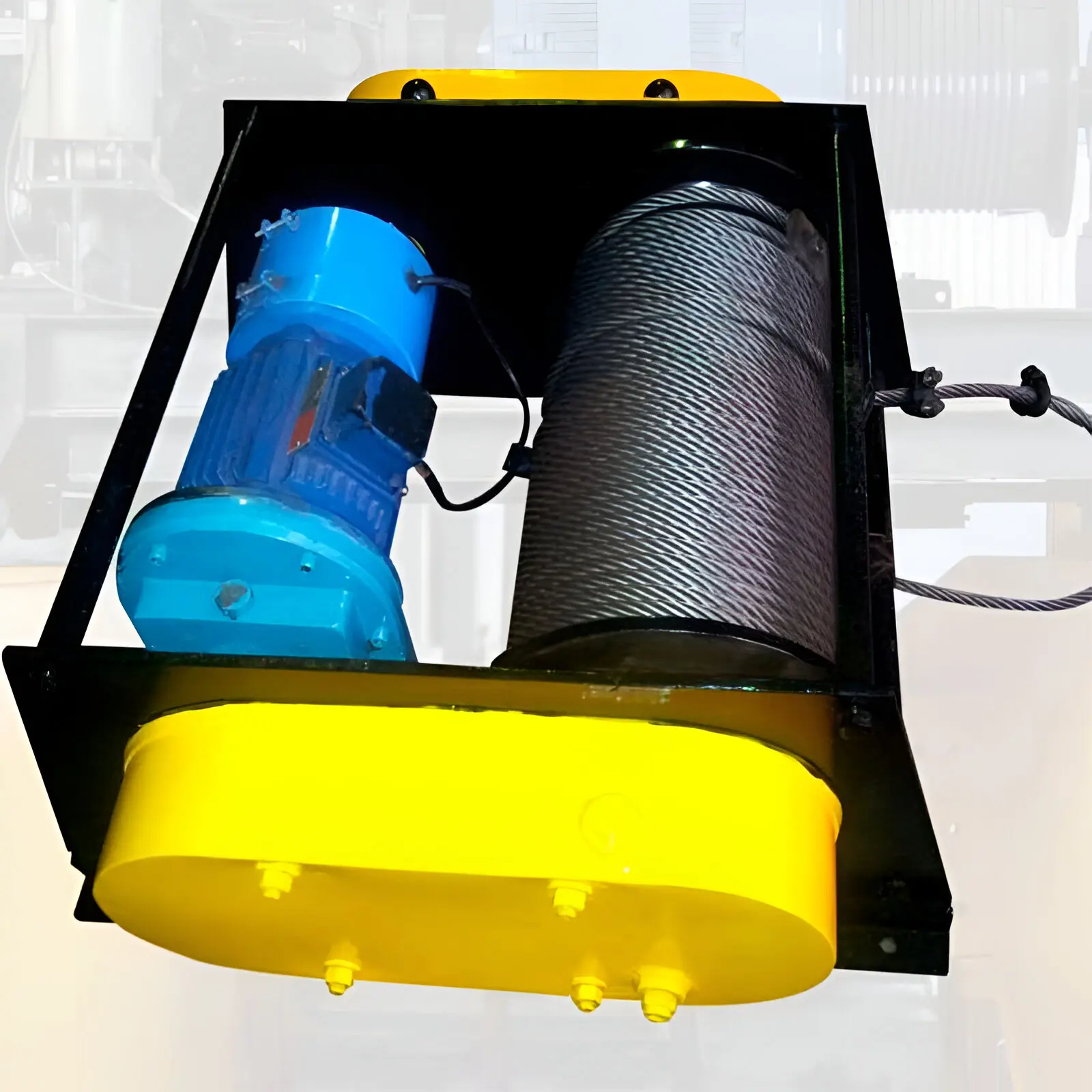

Hoisting Problems

The hoist movement needs to be responsive; the slow and unresponsive hoist will fail to move the load accurately, slow movement or jerking of the hoist. Such problems are often due to issues with hoist mechanisms, apart from problems with the motor and gearboxes. So, inspect the hoist motor for overheating, wear, or damage. So, make sure that the machine is connected to a proper power source and is free from rust.

Apart from that, insufficient lubrication can lead to jerking and slow movements. So regularly lubricate all the moving parts like the gearbox, drum, and cables.

Overload

Each of the cranes has a load lifting capacity (LLC), which is also described by the manufacturer. You should never overdo the given capacity. It will cause unwanted strain on the crane’s structure and motor. Cranes that frequently operate near the maximum load capacity can experience mechanical failure, which can also lead to safety hazards. You should choose the EOT crane, which is equipped with automated load limiters. It will prevent lifting of excessive weights. There can also be an issue with the hoist motor, brakes, or the gear mechanism. Check the components for wear and tear.

Alignment Problems

The cranes can develop issues with their tracking or alignment when the trolley or bridges are unevenly spaced along the tracks. It will cause the crane to sway, move erratically, or even derail in some cases. Misalignment can cause issues with the wheels, tracks, or structural components of the crane. Examine the wheels for signs of any wear and tear. Apart from that, you should also inspect the tracks so that they are aligned properly. The track alignment can be corrected by adjusting the alignment of the rail.

Wrapping Up…

The EOT crane is an essential piece of equipment when it comes to handling heavy loads. So, you need to be aware. By addressing the common issues mentioned above, you can ensure that the load-lifting solution is durable. Regular inspection and quick repairs will ensure safe load lifting. Ganesh Engineering has designed a high-grade load-lifting solution that allows easy lifting of heavy loads. They are robust, efficient, and can withstand extreme climatic conditions, while still delivering high-quality results.

Ganesh Engineering

Ganesh Engineering Co. has been a leading manufacturer of Materials Handling Equipment in India since 2004. In order to provide top-notch products and services, our experienced and dedicated team utilizes the latest technology to achieve perfection.